The three-phase energy meter is used to measure the power of a three-phase supply. The three-phase energy meter is constructed by joining two single-phase meters via the shaft. As a result, the sum represents the entire energy of both components.

Construction of a Three Phase Energy Meter

Combining two single-phase induction types with a common spindle and registering technique results in a three-phase induction type energy meter.

The driving torque of a three-phase meter is the same for both components. This is adjustable by altering the torque.

The current coils of the two components are linked in series during torque adjustment, while the potential coils are connected in parallel. As a result, the fully loaded current is transferred through the coil, producing two opposing torques.

Because the magnitudes of the opposing torques are equivalent, the disc cannot be rotated. If the torques become uneven and the disc begins to revolve, the magnetic shunt must be changed. Before testing the meter, a balancing torque must be acquired.

To provide a balanced torque, the position of the compensator and the brake magnet is set independently for each element.

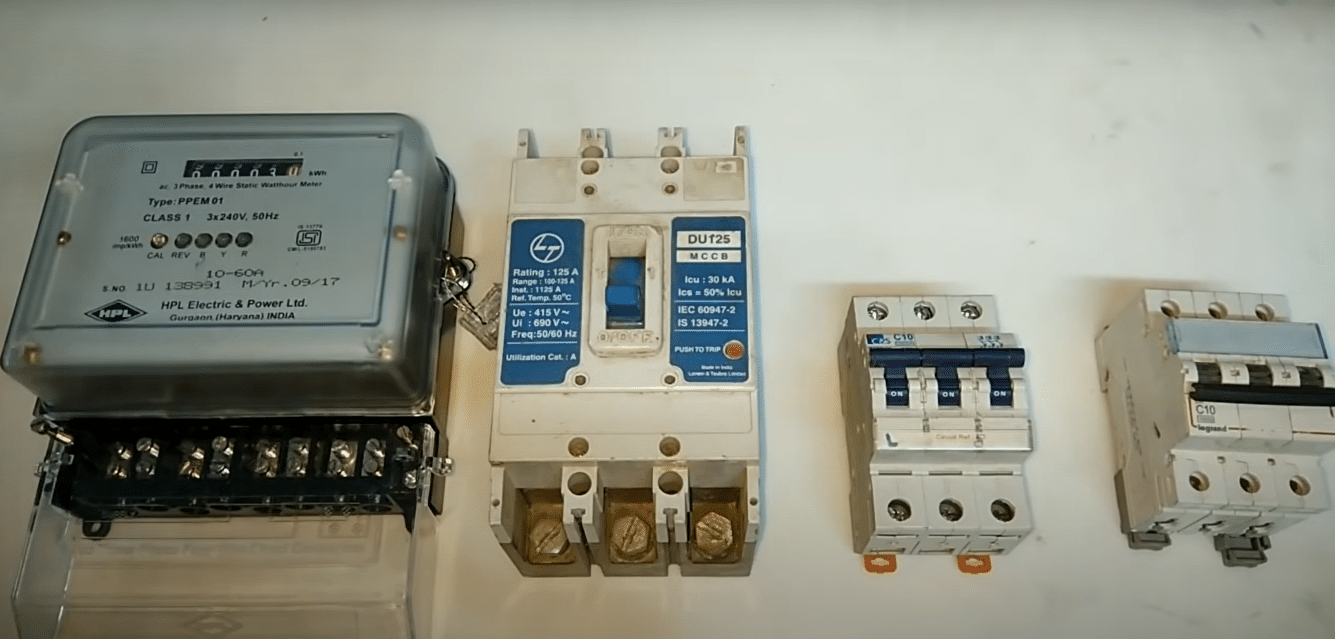

Essential Parts of Three Phase Energy Meter

Here is the list of some essential parts of a three phase meter:

- Moving system

- Registering system

- Driving system

- Braking system

Moving system

The moving system comprises two metal discs (one for each element) linked by a single spindle. As the torque created by each disc is summed together, this torque will be proportionate to the 3-phase power required by the load.

Registering System

The system is linked to the moving system via the pinion and gear train. It continually counts or registers the number of rotations as the discs rotate.

It essentially integrates the power consumption of the three-phase load over a certain time, which is nothing more than energy.

Driving System

When a shunt is paired with a series magnet, it is referred to as an element. It is made up of two parts. These are the wires that are used to wind the electromagnets.

Shunt magnet windings are built so that the torque created by the two magnets is naturally opposing under no-load situations.

Magnetic shunts are utilized to lower the driving torque to zero in the meter. When the discs are not loaded, the location is modified until the discs no longer rotate.

The necessary driving torque is created due to the interaction between the series and shunt magnetic fields on the disc of each element.

Braking system

This system is responsible for providing the appropriate braking action to the discs. Each disc contains its permanent magnet. There is a capability for varying the braking force by altering the location of each brake magnet.

Working of Three-Phase Energy Meter

An energy meter in three phases works similarly to an energy meter in a single phase. The pressure coil and the current coil of the two elements mounted on the shunt and series magnet produce magnetic flux when the load is connected to the meter. A flow of eddy current is created in the flux when it links with the discs.

The torque on discs is produced by the interaction of eddy currents with the flux imposed by the two coils. Because two discs are attached to the same spindle, the torque exerted on both discs adds mechanically. Rotating the shaft corresponds to the 3-phase energy consumed.

Benefits of Three-Phase Meter

Your three-phase connection indicates that you have a large load in your home; you have three-phase so that you may split the loads; the first phase is for lights and fans, and so on. The second step is for the grinder, TV, and other similar items. The third phase is for the alternating current inverter system.

You can use a single-phase up to 20A, but you must use a three-phase after that limit is reached. In the case of an issue in your home, you may separate the phases to isolate the problematic phase from the main DB and continue to operate other phases, ensuring a continuous power supply.

The power consumption is not reduced in three-phase since it is determined by the amount of electricity used each day. A large load in your home indicates a high power cost, regardless of whether it is single-phase or three-phase.